In the fast-paced manufacturing world, staying ahead requires constant innovation and optimization. One crucial aspect is the evaluation of equipment performance and efficiency, and this is where cutting-edge software can make a significant difference. Using such software tools helps with better business growth and makes it easier to manage your business.

This guide explores five critical points on how leveraging equipment efficiency evaluation software can revolutionize your manufacturing processes.

Real-time Performance Monitoring

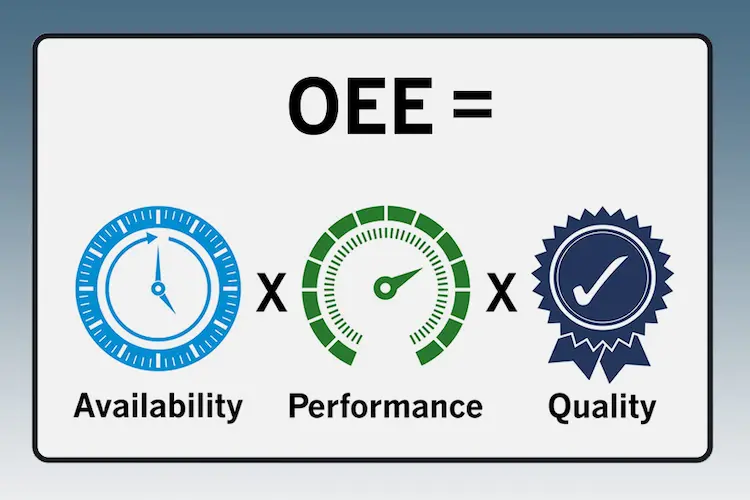

Monitoring equipment performance in real-time is paramount for any manufacturing industry. With advanced OEE Software, manufacturers can gain instant insights into the efficiency of their machinery.

This real-time monitoring enables prompt issue identification and facilitates proactive maintenance, reducing downtime and enhancing overall productivity.

Data-Driven Decision Making

In today’s data-driven era, informed decision-making is a cornerstone of success. Equipment’s overall efficiency evaluation software empowers manufacturing professionals with comprehensive data analytics, providing a detailed overview of equipment performance trends.

By analyzing this data, decision-makers can identify patterns, optimize workflows, and make strategic decisions to improve operational efficiency. Once the operation department of your industry is efficient, the entire production and manufacturing house will see a shift in progress.

Predictive Maintenance For Cost Savings

Unplanned equipment breakdowns can be costly and disruptive. Equipment evaluation software goes beyond simple monitoring by incorporating predictive maintenance capabilities.

By analyzing historical data and performance patterns, the software can predict potential issues before they escalate, allowing manufacturers to schedule maintenance activities proactively. This not only reduces maintenance costs but also extends the lifespan of equipment. Using the software, you can save much of your expensive equipment from going dysfunctional and improve its lifespan.

Streamlined Workflow Integration

Seamless integration with existing manufacturing workflows is crucial for successfully implementing any software solution. Equipment evaluation software is designed to integrate seamlessly with various manufacturing systems.

This ensures that data flows effortlessly between different stages of production, providing a holistic view of the manufacturing process. Such integration facilitates a more streamlined and efficient workflow, minimizing the risk of errors and delays.

Compliance and Quality Assurance

Compliance with industry standards and ensuring product quality are non-negotiable in manufacturing. Equipment evaluation software ensures compliance by continuously monitoring and recording key performance indicators.

This not only helps in meeting regulatory requirements but also contributes to maintaining high-quality standards. The software’s ability to generate detailed reports facilitates easy audits and ensures that the manufacturing process aligns with industry regulations.

Related Post: 10 Best Practices for Mastering QA Auditing

Bottom Line

The utilization of equipment evaluation software is a game-changer for the manufacturing industry. The benefits are diverse and impactful, from real-time performance monitoring to predictive maintenance and streamlined workflow integration.

By embracing this technology, manufacturers can enhance operational efficiency and stay ahead in an increasingly competitive landscape. As the manufacturing industry continues to evolve, those who leverage the power of innovative software solutions will undoubtedly lead the way into the future.