Laser etching and engraving use a laser to create detailed designs on hard surfaces. Sectors like medicine, automobile, pharmaceutical, apparel, jewelry, etc., use these extensively.

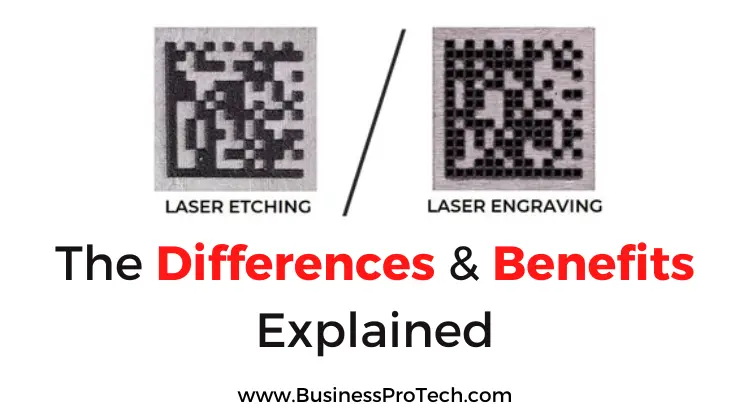

The main difference between the two is the depth of the design. Etching produces a shallow surface, while engraving creates a deep, crisp image with more color contrast and clarity. Both processes can be used for different materials, from wood to plastic to metal. The difference is in how deeply the laser penetrates your material before starting its cut.

Read this article if you need clarification on choosing laser etching or engraving.

What is Laser Etching

Etching is a process that engraves or burns into the surface of a material. In contrast to engraving, which cuts away at the material’s surface, laser etching creates a permanent mark on your item. This technique can create lettering, designs, and other details on glass, metal, and plastic.

What is Laser Engraving

Engraving (also known as laser carving) is a process that uses a laser beam to cut or etch into the surface of materials like wood, glass, metal, and plastic. The material is placed on a table, with the design facing down. The laser beam is then moved across the material’s surface in a pattern that creates an image or text.

The laser can also be used to cut through different types of materials depending on what kind of machine you’re using. This is valuable if you are looking for something specific, such as designs on wood pieces or signs for the outside of your business.

The Benefits of Laser Etching

When it comes to laser etching vs. laser engraving, the most significant difference between these two processes is how they work. Lasers can create a wide range of precision metal parts and products. It is ideal for creating intricate artwork, logos, or designs you want to appear on your finished product.

Laser engraving uses a rotating prismatic lens assembly to direct incoming light beams onto specific material areas. Laser etching uses a high-powered beam of focused light that removes portions of an object’s surface without leaving any unwanted scars behind.

As a result, laser-etched parts have no visible “scrapes” or pitting on their surfaces, which is a benefit if your product design requires an incredibly smooth surface.

The Benefits of Laser Engraving

Engraving machines use a beam of light to etch the surface of a material. It’s possible to fill cavities with paint or another material. It is easier for users to see their engraved markings, even if they’re not looking at them directly. The markings are resistant to wear and tear compared to laser etching.

Conclusion

When choosing between laser etching or engraving, always consider the purpose, type of product used, and usage. For example, if you only want precision in whatever design you want to cut through a material, you’ll likely get better results with laser etching.

However, engraving is best if your material undergoes harsh wear and tear conditions.